REV Gen II Steer Drive

Lab: Texas A&M RAD Lab

Platform: Land-based exploration rover with four independently driven wheels

Key Features: Series Elastic Actuator (SEA) based suspension, fully modular drive units, off-road capable chassis

I led to the mechanical redesign of the steer-and-drive modules and development of the electrical harnessing system from the main battery to the motor controllers and central computer. This included integration of power delivery, signal routing, and connector interface design to ensure robustness during testing and field deployment.

Steer and Drive Redesign

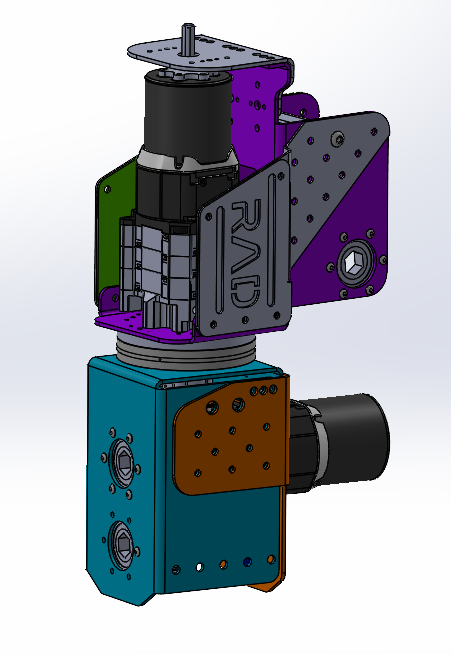

The initial steer-drive design (left) featured a fully sheet metal construction with the drive motor positioned after the steering axis. While functional, it suffered from several critical issues:

1. The drive motor was highly exposed to terrain and debris.

2. The wiring harness was loosely routed and prone to snagging.

3. The steering axis exhibited noticeable backlash.

4. The geartrain was completely open to sand and dust.

5. The drive motor could interfere with the lower suspension arm, limiting suspension travel.

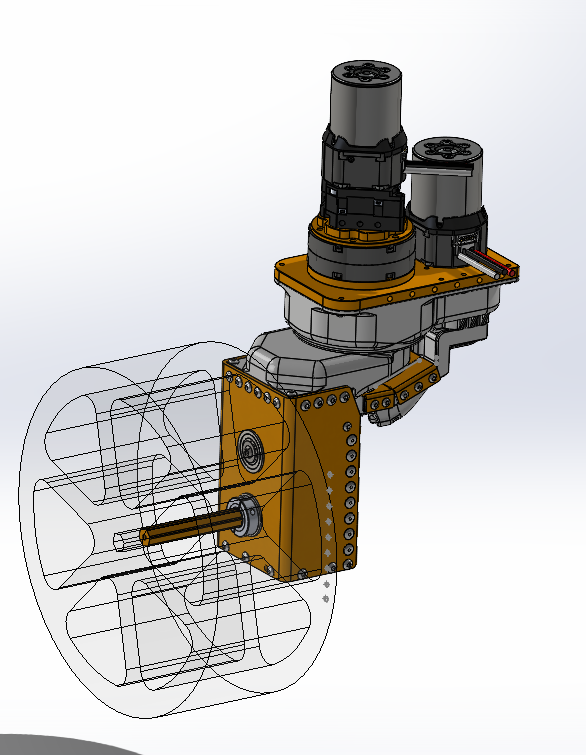

In the updated design (right), I transitioned to a billet + sheet metal construction and repositioned the drive motor before the steering motor. This was made possible using a “double gear” around the steering axis and a bevel gearset to transmit power to the wheel. This change effectively resolved issues 1, 2, and 5.

To address backlash, I implemented a commercially available cycloidal gearbox, mounted directly to the steering axis. Cycloidal drives are extremely rigid and offer minimal backlash, making them ideal for precision steering.

Finally, I enclosed the geartrain with three 3D-printed shrouds and integrated a sealed bearing for ingress protection. All internal gears were upgraded to 4140 steel to resist wear from any debris that may breach the housing.

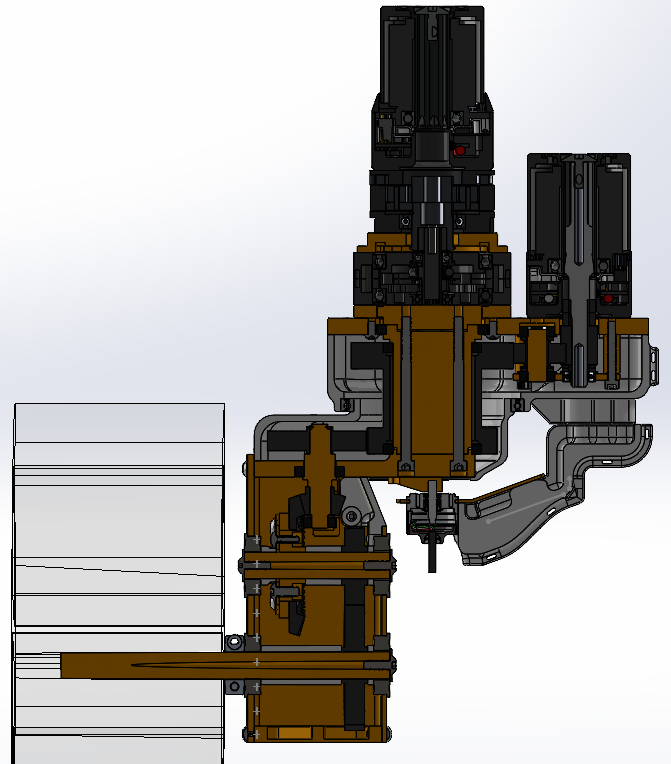

Section view showing internal geartrain, bearing supports, and shaft layout.